We are living in 2022. It is the age of recognising climate change and making efforts to reverse the adverse effects climate change has had on our planet. There is no single factor that has contributed to climate change. Multiple practices, which are now part of our lifestyle, have contributed to the depletion of our natural resources. During the past thirty years, the term “climate change” has gained momentum and worried all the significant stakeholders because it started to have visible impacts on our environment. One is the rise in temperature worldwide, which then contributed to glaciers melting, making the sea-level rise. It has been predicted that Island countries like Srilanka will be underwater in the not-too-distant future This is just the start, which is why action is needed now.

Industrialisation has contributed a great deal towards dragging our world to what it is now. It is on the brink of complete disaster if we do not follow the sustainability protocols that have been highlighted.

In this article, we focus on wet processing (also known as chemical processing) in the textile industry; we will mention the changes made in the textile industry due to the sustainability protocols. The textile industry heavily depends on chemicals to yield an end product that consumers desire. If we take an example of just single jeans, it consumes around 800 to 1000 litres of water along with many chemicals to get an authentic denim look. But in recent years, small but considerable chemical processing changes have been made in the textile industry to ensure the waste water is not as toxic as it used to be. It will ultimately have a less negative impact on the ocean’s ecosystem and us.

Let’s first get a brief idea of what comes under the chemical processing of textiles. It is one of the most critical operations in modern textiles. No fabric or textile product is complete without it. One must think, why is that? Well, it adds value to the end product. Consider the example of a simple plain white t-shirt; even that T-shirt has to go through bleaching for a bright white colour, and softeners are applied to give it a softer hand feel. The shirt has no aesthetic appeal to fashion clothes, yet it goes through at least two chemical processes in finishing.

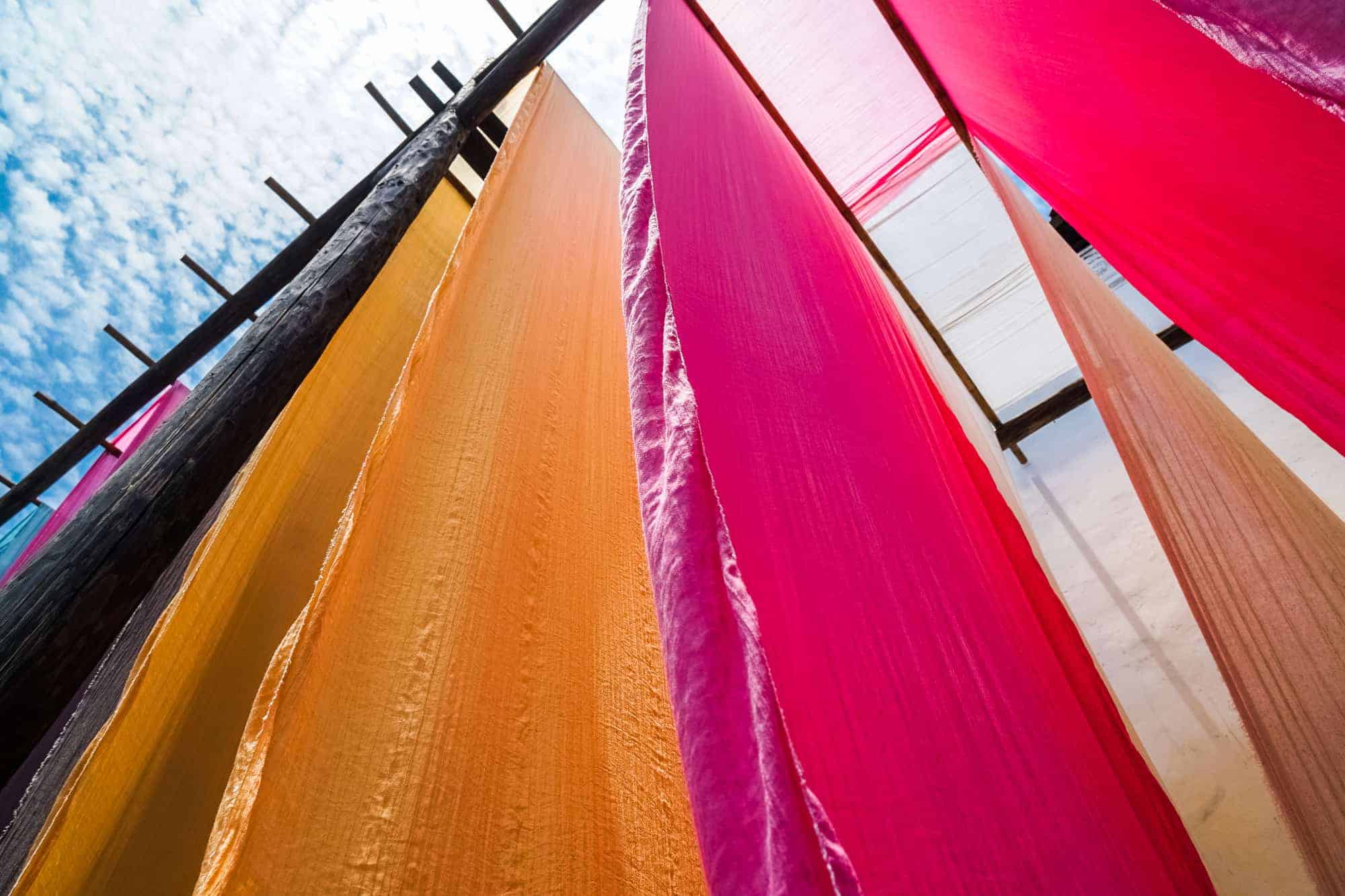

Wet processing of textiles is essential in textile manufacturing because it adds the most value to the fabrics by enhancing their aesthetic appeal, comfort, and properties. However, a significant amount of water is utilised as the medium, which becomes polluted with unfixed colourants and toxins during the processing techniques and is released as wastewater. This effluent’s chemical cocktail makes it hard to treat or biodegrade. It causes pollution and increases the demand for high-quality water for processing. Natural fibres, such as cotton, require water and fertilisers to grow, whereas synthetic fibres need petroleum resources for production. Energy is also required at several stages of the textile production process.

Chemical processing has two parts, colouring/dyeing and finishing. These steps have not changed over the years, but there have been variations due to the rise in demand for innovative products. In short, from cleaning of raw materials to dyeing to finishing, it all comes under the umbrella of chemical processing. During the process, excessive water and energy are consumed along with many chemicals.

Now let’s look at the changes made in the chemical processing of textiles because of sustainability for a better future.

Natural dyes were the common choice at first when the industry was not yet advanced, and only small-scale productions used to take place. However, as the industry expanded and demand increased exponentially, natural dyes became expensive. That is when synthetic dyes like azo dyes were introduced as they are cost-effective and yield the desired properties. Azo dyes make up around 70% of the total organic dyes. They have multiple applications like being used in natural and synthetic fabrics, inks, printing, and much more.

However, two authorities, namely the state of California and the European Union (EU), have banned numerous azo dyes. It was because they are termed as carcinogenic, and this claim is backed by research. The reason is that once azo dyes come in contact with sweat from the body, the parent azo dyes go through cleavage due to increased pH, which is when the aromatic amines are released. The carcinogenic amines released through azo dyes can contain several chemicals that are known to cause harmful effects on reproductive systems. Several countries like India, Vietnam, and China have also banned the use of azo dyes containing carcinogenic chemicals.

Using enzymes in textile processing is not a new concept, but it is being used widely now compared to the proportions used before. The reason was other chemicals were used, like caustic soda in scouring, acids and alkalis in desizing, hydrogen peroxide in bleaching, and stone washing in denim garments.

However, the alternative to all these chemicals and finishing has been found in using enzymes. How?

In desizing, enzymes are used that remove the starch without any harm to fibres or fabric, unlike when starch is released with acid or alkalis. Scouring cleans the fabric by using hydrogen peroxide, which, along with removing impurities, also damages the fibre structure to some extent. But now bioscouring has been introduced in which enzymes remove the contaminants without damaging the structures of the fibre, reducing its strength. Similarly, enzymes are also taking over in denim garments washing by replacing stone wash with a cellulase enzyme wash that has a very similar effect as was achieved by pumice stone wash. The enzyme wash is known as bio stone wash.

Do note that enzymes are not entirely a new concept, but their use has exceeded in the past 20 years due to the world’s focus on sustainability and thus saving the planet.

Surfactants are textile auxiliaries that are used not only in one but many processes in finishing, such as scouring, lubrication, and dyeing.

Commonly used surfactants are alkyl phenol ethoxylates. These are not harmful to humans, but they are observed to have a detrimental effect on marine life. For this reason, biosurfactants are introduced that are derived from microorganisms. The common biosurfactants are aminoacid lipids, lipoproteins, and lipotides. These are antibiotics for microorganisms that also happen to have surfactant properties. So, biosurfactants act not only as an auxiliary for smooth textile processing but also have antimicrobial properties. Hence, using this is only a plus, which is why this option is being used and explored for further development.

The above-mentioned chemical processes changes in textiles were only a few of many that have occurred in the past several years. The reason is textile chemical processing is under the constant radar of the higher authorities for its excessive use of harmful chemicals, large amounts of water, and energy. If no changes are made, then the toxicity and waste from these processes can lead our world to a scary future. For this reason, governments and organisations are continuously making laws and policies to bring the textile industry in line with environmental compliances.

Ultimately, all of these changes have one goal: to create a safe and comfortable planet for not only us human beings but animals too.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Create your free account and begin your sustainability journey.