Hemp fibres are one of the most common types of natural fibres obtained from the Cannabis species of the hemp plant. Hemp fibre is also known as Industrial Hemp as it is consumed for industrial purposes such as ropes and sails due to its versatile and durable characteristics.

In addition, due to their biodegradability and low density compared to other regenerated fibres, these fibres are now widely used as reinforcements in composite materials. Hemp fibre is grown and processed without the application of pesticides or other chemicals. As a result, hemp fibre is both natural and environmentally friendly. This aspect of sustainability has made it a popular choice among clothing and apparel producers. Famous brands around the world are carrying out marketing campaigns for the promotion of hemp fibre for textile products.

Hemp plantation or farming is not legal in every country due to its potential use in narcotics. The chemical compound in Hemp responsible for the psychoactive effect is known as THC or Tetrahydrocannabinol. The concentration level of the THC compound in the Hemp at the time of cultivation is checked, and only the crop containing the chemical quantity within the tolerance range is allowed to harvest.

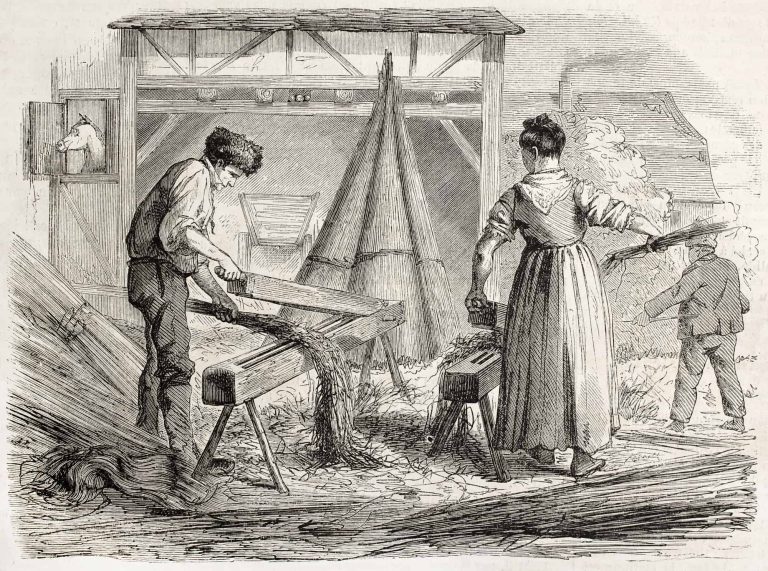

Hemp is so old that it’s still a source of debate as to when and where it was grown. It is said to have originated in the Middle East around 8000 BC. However, others believe that it was initially farmed in Asia around 5000 BC when hemp plants grew in populous areas of China and were subsequently utilised commercially for medicine. Around 2800 BC, Chinese legend Shen Nung taught his people to weave hemp plants into garments due to their strength and abundance. Later on, it started to spread in Europe, where it was equally liked by the Kings, commoners, farmers, and naval commanders because of its versatility.

China is the world’s largest Hemp fibre producer. Although hemp cultivation was prohibited in China from 1985 to 2010, still China is producing Hemp for over half of the global supply, which is more likely to expand in the future.

There are two types of hemp fibre;

Bast fibres often account for up to 20-30% of the stalk, depending on the cultivar or usage type and planting density.

Bast fibres come in two varieties:

Hurd is generally found in the inner core of hemp stalks. Its length is approximately 0.5 mm, which is quite a short length. It contains up to 70-80 percent of the stalk, and the remaining 20-30 percent contain lignin.

Due to the versatility of Hemp fibre, it has multiple uses, which are mentioned below;

Hemp is less expensive than wood, and it is a better insulation material.

Furthermore, why use something more expensive, more difficult to obtain, and less effective than it should be when a less priced and more efficient option exists? Hemp is more insulating and can easily be packed between building components.

Textiles have been produced from hemp fibre since antiquity. It is both abundantly available and cultivable. It is less expensive than most other organic fibres and far more environmentally friendly than chemically manufactured textiles. Hemp cloth is also suitable for sensitive people and does not create allergies.

Hemp fibres are now most commonly used to make papers. Before hemp fibres, Plants have always been used to make paper.

At one time, thin strips of birch bark were used as paper. However, this natural paper was not always made from dying birch trees, as is ecologically feasible.

Later on, forest trees were cut to make paper. This resulted in extensive deforestation, which had an adverse impact on the environment, and it became a critical situation to find an alternative to making papers. Thus, hemp fibres help to resolve this issue.

Since Hemp is easy to grow and flexible to cultivate, it is used as a raw material to make high-quality paper from hemp fibre for our needs. This would serve as an organic and natural supply of paper, which is one of the most important materials in our daily living.

Hemp fibres are used to construct ropes and cords because of their high tensile strength.

Hemp fibres are increasingly being used in common applications as the modern world looks for new organic and ecological materials.

Since shoes bear the total of our body weight, they wear out quickly; hence hemp fibres have been utilised to make tough shoes that provide both ease and durability.

Leather is a material that has been used for a long time to manufacture long-lasting shoes. However, the process of making leather from animal skin is not only time-consuming but also pricey.

Hemp fibres are a far better solution to make shoes, which have been tried by numerous designers and shoemakers as well.

They’re easy to come by and grow in large quantities. Even if grown as an industrial crop, the overall cost of production is inexpensive and has no negative impact on the planet’s flora and fauna.

Given below are some of the important points which need to be taken care of to make hemp fabric durable;

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Create your free account and begin your sustainability journey.